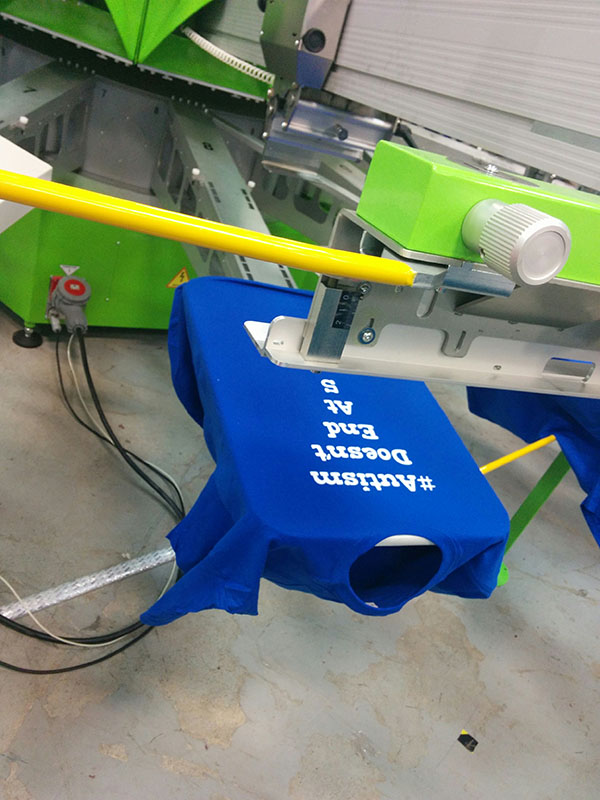

ROQ Screen Printing Press

Entripy is happy to welcome a new addition to our factory floor. This green monster (which resembles an octopus) will add much needed production capability to help us meet our ever growing demand.

The S ROQ press hails from Portugal and is used to decorate garments using the screen printing process. Screen printing is the most common decoration method for custom t-shirts, sweatshirts and other custom clothing items. In screen printing, a custom design is exposed onto a mesh screen, washed and is then set up on the press.

Using a squeegee-type blade, the ink is passed through the screen onto the shirt. The ink is then dry cured through a conveyer dryer which raises the temperature of the ink to 320 degrees Fahrenheit.

Completing Custom Clothing Orders Faster

Prior to the arrival of the ROQ, Entripy had 5 M&R automatic presses that had the capacity to output over 4,000 prints per hour plus an A.S.P.E Rapid Tag Print that produces 800 prints per hour. With the addition of the new S ROQ, which can print 800-1000 prints per hour, Entripy can now produce 6,000 prints per hour! This increase in output means Entripy can fulfill customer orders faster.

Not only will our new printing press improve our productivity, it will also help us to provide our customers with the highest quality work. ROQ presses are known for being fast, efficient and highly accurate. Their honeycomb pallet allows for the best detail when printing.

Our new press will also help Entripy to continue our efforts to reduce energy consumption and be more environmentally friendly. The S ROQ’s honeycomb aluminum pallets allow for better heat control and maximize energy to heat up pallets. Plus, the pallets are lightweight which means it takes less energy to move them around the press.

Entripy prides itself as being a company that employs the latest technology in order to be a leader in the custom apparel industry. Watch this video to see our new ROQ screen printing press in action!